At the beginning of April, we had an idea to step into the breach of PPE availability and put together a short-term project using 3D printers to make face shields for front line workers.

We were busy trialling designs made in Denmark and the Czech Republic on our existing 3D printers. We had used a small amount of funding from an existing grant programme from the Sussex Community Foundation to make the first few shields and to understand what would be needed if we needed to upscale. Concerns about the lack of face shield availability in the area was raised as urgent in the local COBRA meeting, attended by one of our directors. This made the decision for us.

TechResort rarely has much in the way of unrestricted financial reserves, and we’d already committed to continue paying our young, part time workforce so they could rely on their income from us for a few months. Nevertheless, our directors agreed that we would set up the project first with our remaining reserves and hope we could get some financial support later. We wanted to ensure that the people who urgently needed face shields didn’t have to wait any longer than necessary.

Getting started

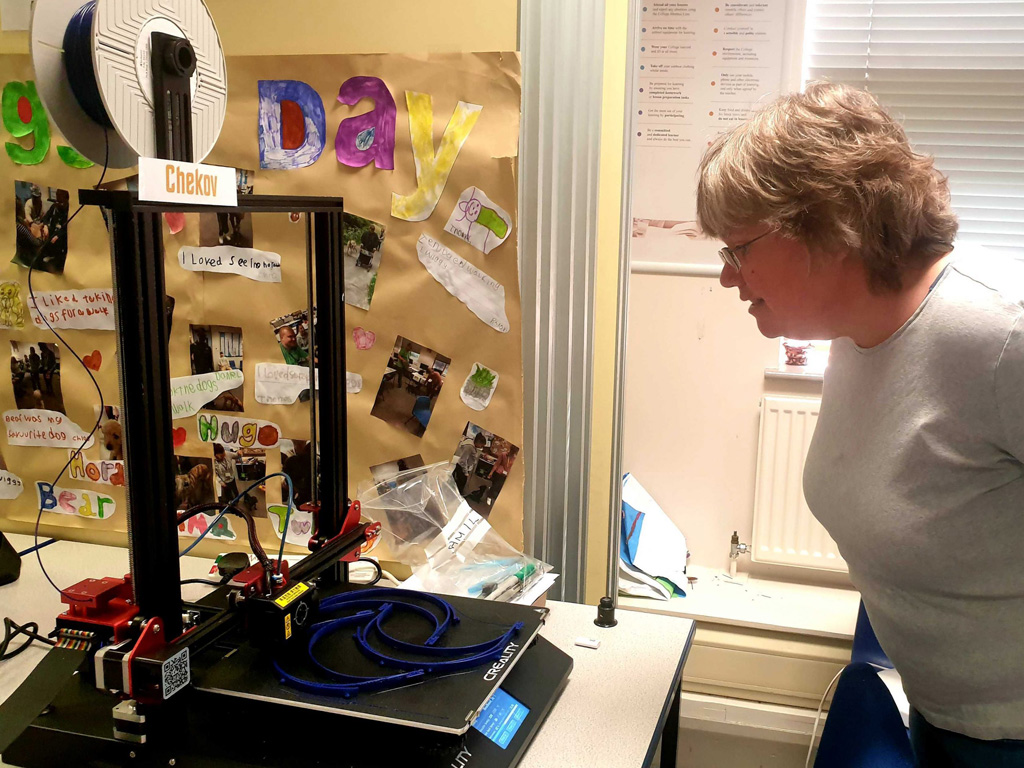

Within a week of taking the decision, we’d set up our “farm” of six 3D printers in a large room close to our HQ at East Sussex College in Eastbourne.

All the folk at TechResort are makers at heart, but manufacture is a step further. Manufacture means process, consistency, improvement and quality. The first few days frustrated us as we tried to get the best from our new printers, but still produce face shields as quickly as we could.

3D printing is a slow process – great for prototyping, less so for repeat jobs – but it was the technology we had to hand. Also, as a non-specialist tool, we knew the printers we bought, and the methods we learned could be applied to our wider work in future. On the whole this is a good trade-off for us.

How to make a face shield

There are many processes required to complete a faceshield – the 3D printed headband is just the start. The designs we chose, called Prusa and Verkstan, had an A4 sheet of clear plastic to form the face plate. They were attached to the headband by studs printed into them – this meant that the holes we punched into the clear sheet had to be placed with precision. In turn this meant buying a large, adjustable, hole punch and designing jigs that would help us set the punch up accurately.

A printed headband has to be checked over to make sure it doesn’t have rough patches, mis-printed areas, or cracks. Some of these flaws can be fixed with a Stanley knife to remove excess material, and we were ruthless in our QA.

We had to be vigilant about cleanliness – from thoroughly cleaning all work surfaces each day, to cleaning print beds and all tools frequently. Everyone washed their hands often, and avoided touching the headbands as far as possible. The final part of this is to pack all pieces into sealable plastic bags with the date of sealing written on the label.

Putting all this together meant our shopping lists became very diverse – starting with 3D filament (over 50 kgs of it), moving onto sealable plastic bags in bulk boxes, litres of surface cleaner, a lake of Isopropyl Alcohol (not literally), kilometers of paper cleaning roll and elastic, sticky labels, marker pens… and the list goes on.

How we’ve done

So far we’ve made over 1700 face shields and most of them have been donated locally – to GP surgeries, to care homes, and community medics and caregivers. About 400 were sent to the 3D Crowd Sussex hub (in Worthing) to be used for a large hospital order they desperately needed to fulfil.

At the peak, around 250 shields were being collected each week and we had to increase our working hours to match the requirements. We had rotas and collection processes to ensure we minimised the number of people on site at any one time.

We even decided to learn about dye sublimation printing, and bought some equipment to make individual mugs for all the farmhands so that we weren’t sharing them. Tea drinking (with biscuits) is essential to keep farmhands hydrated!

All along we’ve been helped by the college (thank you, Estates Team – you’ve been brilliant), by organisations and individual donations, by our volunteers and by our staff. It’s really been a team effort!

This week, the college requested two of the rooms we were using to be vacated so that they can welcome students back. We have about 150 faceshields packed and available to frontline workers who need them, and we have reserved some materials so that we can make more shields quickly if demand starts to pick up again.

Watch this space

For now, the “farm” has gone into hibernation and we’re looking what’s next. Our local online marketplace, One Eastbourne, goes live tomorrow and that should be a big help to Eastbourne’s recovery.

It’s clear that digital know how is likely to become even more important to everyone as employers, educators and other organisations re-examine priorities and procedures. This means more people will need to develop more digital skills than ever before.

Working with some volunteers who thought that “tech isn’t their thing”, and seeing them develop the very skills that our own workforce has in abundance shows that TechResort is well placed to do something about the local skills shortage.

So this isn’t the end of our lockdown project – it’s the beginning of a new one. Something we’re about to get on and… DO.